Industrie 4.0 component and the concept of the Asset Administration Shell

IEC/TC65 WG 24

IEC 63278-1 ED1 „Asset administration shell for industrial applications – Part 1: Administration shell structure

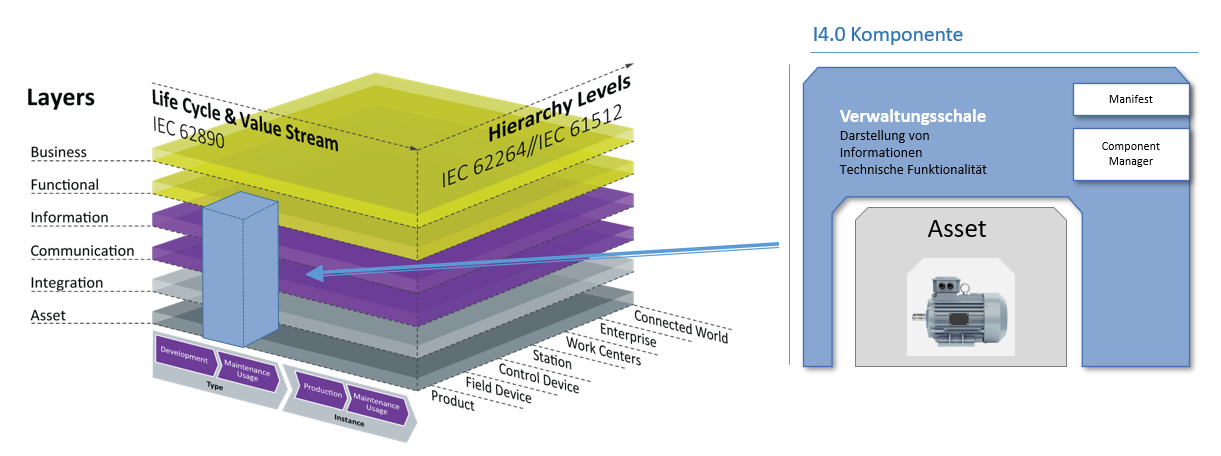

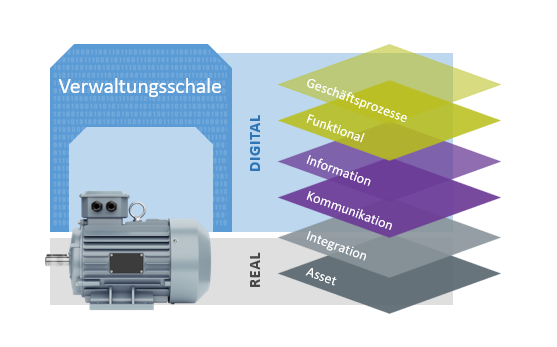

In order to make the information world available, objects are described by means of their properties in such a way that this description can be assigned to the respective object in the information world as a whole and put in relation to other objects. According to the concept of the digital factory (IEC TS 62832-1), a physical or logical object that has an actual or perceived value for an organization and is therefore managed is called an asset.

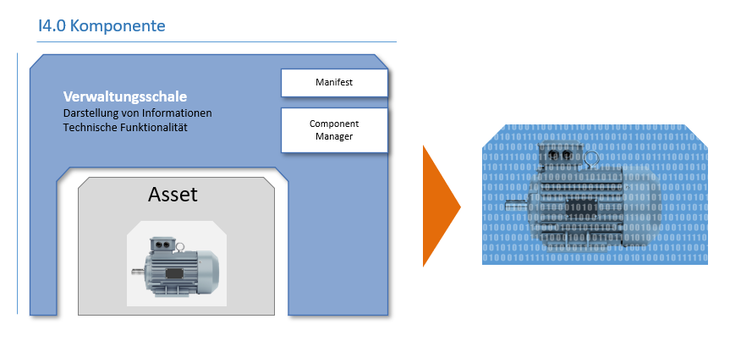

The term "Asset Administration Shell" is therefore based on the idea that the information world encloses the Asset (e.g. part of an I4.0 component) like a shell, as illustrated in the figure.

As shown in the application example below, such an I4.0 component can represent a machine tool, for example. The information is stored using characteristics whose semantics are defined in such a way that the system can standardize the relevant information and make it available via the corresponding RAMI 4.0 layers.

The result paper does not contain a final IT specification or implementation requirement and was initially used to clarify what features, data and functions are typically stored in a management shell. The document Management Shell in Detail (VWSiD) Part 1 defines the structure, that is, the serialization and exchange format of a management shell. Part 1 of VWSiD focuses on the exact definition of the data model using a UML diagram, its serialization in XML and JSON and the definition of a simple and secure transport of management shells between two technical infrastructures in a container

Current developments and recommendations for action

At IEC/TC 65 the project IEC 63278 ED1 "Asset administration shell for industrial applications - Part 1: Administration shell structure" was started in the newly founded Working Group 24 under German project management. This sets the course for developing the concepts of the administration shell into an international standard or series of standards. Further parts of the IEC 63278 series as well as other standards are required to internationalize the administration shell concept. This involves both the description of infrastructure mechanisms such as the I4.0 language and the description of submodels for specific classes of assets

· Generic requirements for submodels

Submodels essentially consist of features and references to functions, methods, services, documents and other complex issues that are not part of the submodel itself. If possible, submodels should have a self-contained view of an aspect of the asset and some use or serve a scenario. An example of this is energy management, so that in the energy management submodel all relevant features can be provided via interfaces.

· Communication of I4.0 components

The interoperability between I4.0 components depends crucially on the contents of the management shell and so it is the main task of the management shell to register and make available the data and functions of all relevant assets including products and entire production systems in a standardized way throughout their life cycle.

Use case: "Integration of a machine tool at the user's site using standardized description of the manufacturing properties".

In the application case it is illustrated how the integration of these machines can be simplified for a user by standardizing the manufacturing characteristics of machines. The essential value-added relationships between the companies involved are shown in the following figure.

A consortium, such as the OPC Foundation, develops a specification. An industry, such as machine tool manufacturers, agrees to develop the OPC UA standard, which is also available as the IEC 62541 series of standards, for their industry by developing an OPC UA Companion Specification for their industry. The individual machine tool manufacturers support this and then offer machine tools on the market that have implemented this OPC UA Companion Specification, but also have unique selling points. Machine tool users then benefit from a simplified integration of machine tools in their plant, but also from cross-manufacturer condition monitoring and predictive maintenance, a technology-open optimization of production or a simplified retrofit of existing machines.

This use case is relevant for standardization in so far as it shows possibilities of how mechanisms already established on the market today should be further developed in order to create additional benefits.