International Cooperations

Go Global Industrie 4.0 Project

Jointly tackling the transnational opportunities and challenges of digitalization is a core idea in the standardization of Industry 4.0. The objective for successful international standardization of industrial equipment is the consensual harmonization of Industry 4.0 concepts at a global level.

With the GoGlobal Industrie 4.0 funding project, the Federal Ministry for Economic Affairs and Energy (BMWi) has been supporting the global harmonization of national Industrie 4.0 concepts since December 2017.

The cooperating countries are generally actively represented in international standardization, so that early, consensual cooperation is expedient. The respective country cooperations are used to synchronize these direct discussion channels with the work in the corresponding international standardization committees.

The respective cooperations address the most important countries in the ISO/IEC committees listed above and, as already described, require a high degree of cooperation and transparency in the design of joint results.

Networking of national Industry 4.0 concepts and their global harmonization through norms and standards

Jointly tackling the transnational opportunities and challenges of digitalization is a core idea in standardization for Industry 4.0. The objective for successful international standardization for industrial equipment is the consensual harmonization of Industry 4.0 concepts at a global level. Initial harmonization work on reference architecture models for smart manufacturing is proving successful here and still requires extensive cooperation between countries to harmonize a binding regulatory model.

In the area of international cooperation, a distinction must be made between bilateral and multilateral country cooperation. Multilateral cooperation includes political alliances such as the G20 and the European Union. The activities and initiatives of the European Commission are discussed separately.

Within Europe, there are bilateral or trilateral agreements with EU countries. These collaborations form the basis for the harmonization of future work. The initiatives for the digitalization of production from Germany, France and Italy have agreed on trilateral cooperation in order to strengthen and support the digitalization processes in their respective manufacturing sectors. In addition, European efforts are to be promoted.

The cooperating countries are generally actively represented in international standardization, so that early, consensual cooperation is expedient. In doing so, the respective country cooperation is used to synchronize these direct discussion channels with the work in the corresponding international standardization bodies.

IEC-International Electrotechnical Commission

The DKE German Commission for Electrical, Electronic & Information Technologies in DIN and VDE represents German interests in the IEC with headquarters in Geneva/Switzerland. Germany, with its approx. 3,500 experts, holds a leading position in the IEC and provides approx. 21% of the committee chairs and 20% of the secretaries.

IEC System Committee Smart Manufacturing (IEC/SyC)

The IEC Standardization Evaluation Group Smart Manufacturing (IEC/SEG 7), whose main task was to develop a concept for the overarching and bundled processing of the topic of smart manufacturing, completed its work in 2017 and developed a proposal for the mandate of the newly established IEC Systems Committee Smart Manufacturing (IEC/SyC). The IEC/SyC was established directly under the IEC Standardization Management Board (SMB) and began its work in the second quarter of 2018. In addition to coordinating standardization activities and identifying gaps and overlaps, the tasks of the IEC/SyC include in particular the cooperation of relevant standardization organizations and Standardization Development Organizations (SDO).

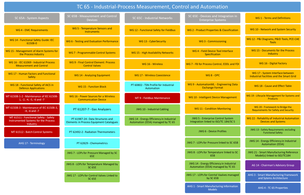

IEC Technical Committee TC 65

The Technical Committee IEC/TC 65 consists of 29 active member states and 18 observer states (so-called observers) and thus comprises a total of 47 states. In terms of content, IEC/TC 65 works on international standards for systems and elements. These are used in industrial process measurement and control in continuous and discontinuous processes. IEC/TC 65 also coordinates the standardization of related elements. Standardization at international level is thus designed for equipment and systems with electrical, pneumatic, hydraulic, mechanical or other measurement and/or control systems. In addition, various subgroups have been established in the field of Smart Manufacturing/Industry 4.0.

ISO-International Organization for Standardization

DIN represents German interests in ISO, which has its headquarters in Geneva/Switzerland. With over 11,000 experts, Germany holds a leading position in ISO, is represented in 327 Technical Committees (TC) and runs 54 secretariats.

ISO: Technical Committee 184 (ISO/TC 184)

The Technical Committee ISO/TC 184 consists of 20 active member states and 24 observer states (so-called observers) and thus comprises a total of 44 states. In terms of content, ISO/TC 184 works on standardization in the field of automation systems and their integration for the design, procurement, manufacture, production and delivery, support, maintenance and disposal of products and their associated services. The standardization areas include information systems, automation and control systems and integration technologies.

ISO: Smart Manufacturing Coordinating Committee (ISO/SMCC)

In September 2016, the ISO Industry 4.0 Strategy Group successfully concluded its activities. The ISO/SMCC was founded as a successor committee to continue the international activities. It existed for a period of two years and was made up of representatives from the relevant technical committees. In total, representatives from 21 ISO committees and one representative each from IEC and ITU have been nominated to participate. Under German leadership, the ISO/SMCC has been actively promoting international work on the topic of Industrie 4.0 ever since. The aim here is to coordinate the topic across the board and develop implementation recommendations, particularly with regard to a joint international approach. At the same time, a national mirror committee was implemented in order to offer interested parties a national platform to play a key role in shaping the international work.

ISO: Strategic Advisory Group (ISO/SAG) Industry 4.0

One of the main tasks of the ISO/SAG I4.0 is to develop a precise definition of Industry 4.0 and to take stock of the standards, standards projects and use cases that already exist or are in progress. Based on these findings, standardization gaps are to be identified and recommendations for action are to be developed.

ISO/IEC Joint Working Group 21 (ISO/IEC JWG 21)

Due to the technical overlap between Smart Manufacturing and Industrie 4.0 on the part of IEC and ISO, ISO/IEC JWG 21 was founded and the representatives of IEC and ISO met for the first time in June 2017 in Frankfurt am Main for the constituent meeting.

The main task of ISO/IEC JWG 21 is to develop smart manufacturing reference models, in particular the various aspects relating to the life cycle and the technical and/or organizational hierarchies of objects (assets). In addition, the development of a basic architecture for smart manufacturing components is planned as an essential part of the virtual representation of objects (Industry 4.0 component).

The contributions from the various countries will be consolidated into uniform models that do not contradict each other and a new work item offering will be developed and disseminated in line with the results.